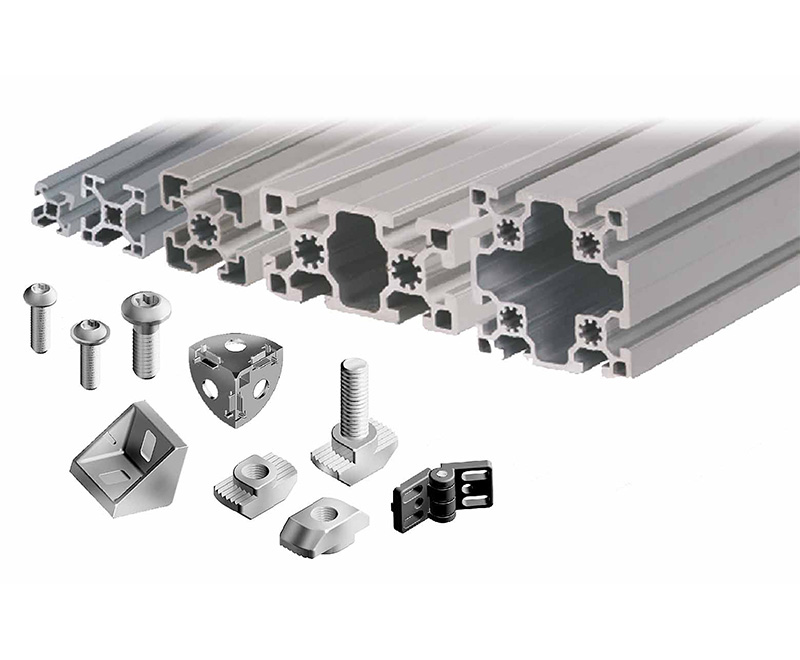

How do I choose an aluminium profile?

In the world of construction, manufacturing, and DIY projects, aluminium profiles have become an indispensable component due to their versatility and durability. Whether you are working on a home improvement project or a large-scale industrial construction, choosing the right aluminium profile is crucial for the success of your endeavor. With a myriad of options available in the market, it's essential to understand the key factors that influence your decision.

1. Purpose and Application:

Before delving into the myriad of options, it's essential to define the purpose and application of the aluminium profile. Different projects require different profiles. For instance, if you are working on a lightweight structure, a standard extruded profile might suffice. However, heavy-duty applications might demand a robust, specially designed profile.

2. Alloy Selection:

Aluminium profiles are available in various alloys, each offering unique characteristics. The most common alloys are 6061 and 6063. 6061 is known for its high strength and excellent corrosion resistance, making it suitable for structural applications. On the other hand, 6063 is prized for its extrudability, making it ideal for intricate shapes and designs. Consider the specific properties required for your project and choose the alloy accordingly.

3. Profile Dimensions:

The dimensions of the aluminium profile flame play a crucial role in determining its suitability for a particular application. Consider factors such as length, width, and thickness. Make sure to choose dimensions that align with the structural requirements of your project. Oversized or undersized profiles can compromise the integrity and stability of the structure.

4. Surface Finish:

Aluminium profiles come with various surface finishes, ranging from mill finish to anodized or powder-coated options. The choice of finish depends on both functional and aesthetic considerations. Anodized finishes provide increased corrosion resistance and durability, while powder-coated finishes offer a wide range of color options for a more polished appearance.

5. Tolerance and Precision:

In precision-driven projects, where tight tolerances are crucial, it's essential to select aluminium profiles that meet the required precision standards. Profiles with higher precision ensure a seamless fit, reducing the need for additional modifications and adjustments during the assembly process.

6. Thermal Properties:

Aluminium is known for its excellent thermal conductivity. However, in applications where thermal considerations are critical, such as in the construction of energy-efficient structures, thermal break profiles may be necessary. These profiles feature a thermal barrier that reduces heat transfer, enhancing the overall energy efficiency of the structure.

7. Supplier Reputation:

Choosing a reputable supplier is as important as selecting the right profile. Research suppliers thoroughly, considering factors such as their experience, customer reviews, and adherence to quality standards. A reliable supplier not only ensures the quality of the aluminium profiles but also provides valuable support and expertise throughout your project.

8. Cost Considerations:

While quality should be a top priority, it's essential to consider your budget constraints. Compare prices from different suppliers and balance cost considerations with the desired specifications. Sometimes, investing in higher-quality profiles upfront can result in long-term savings due to increased durability and reduced maintenance costs.

In conclusion, choosing the right aluminium profile requires a thoughtful analysis of your project's specific requirements. By considering factors such as purpose, alloy selection, dimensions, surface finish, precision, thermal properties, supplier reputation, and cost, you can make an informed decision that ensures the success and longevity of your project.

评论

发表评论